The patented RSP functional principle

The ESE suction principle

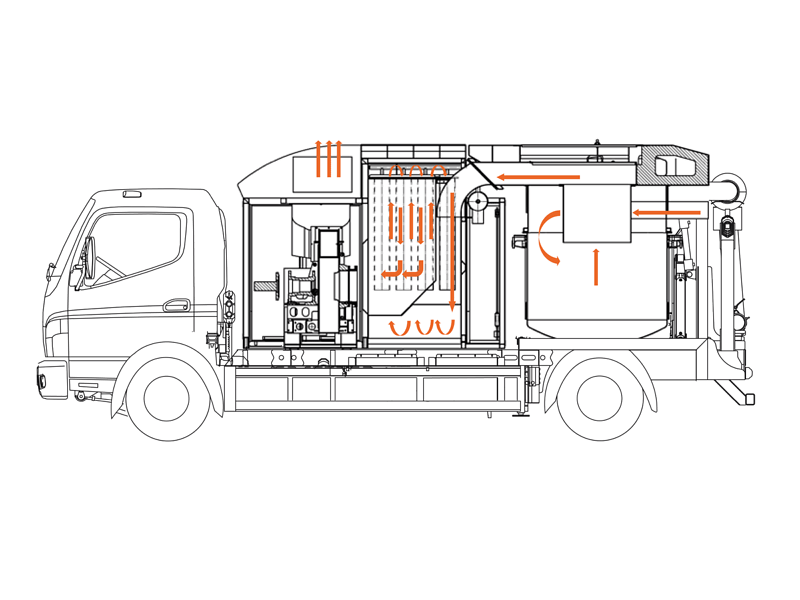

Our vehicles operate according to the internationally patented RSP suction principle. This method guarantees maximum gravity separation, minimum filter load and therefore consistently high suction performance. In this process, the fan generates an air flow of up to 44,000 m³/h and a maximum negative pressure of 55,000 Pa. The suction hose can be moved hydraulically in three dimensions via the support. In the area of the suction crown, the material is entrained by the air flow. All media and solid particles up to a size of 250 mm can be sucked up. All essential particles are deposited in the collection chamber due to the air calming and rotation.

The air flow is further cleaned and dried via the separating chamber. The position of the collection container guarantees optimum axle loading of the vehicle. The final dust is absorbed by the ultra-fine filter unit. The cleaned air is expelled upwards over a large area via a sound insulation unit. The ultra-fine filters are cleaned using compressed air. During the lateral emptying process, not only the collection chamber but also the separation chambers and the ultra-fine filters are emptied. All superstructure functions can be operated via a radio remote control.

The powerful cyclone for our City model

In the cyclone separator, the air filled with material as a carrier is set in a rotary motion by its own flow speed and the corresponding design of the separator. The centrifugal forces acting on the particles accelerate them radially outwards. The particles in the air flow lose their kinetic energy on the outer wall due to friction and fall downwards into the collection area. The cleaned air flow is discharged centrally upwards via an immersion tube.