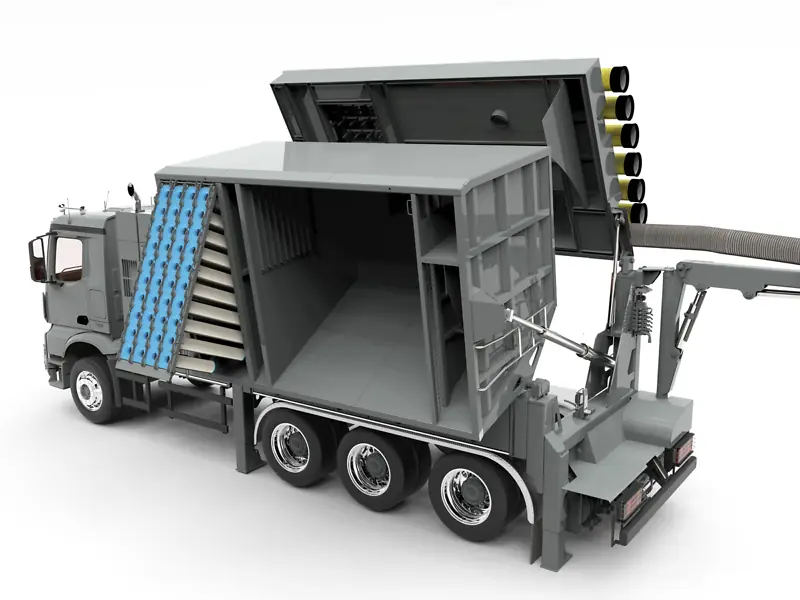

The material container

PATENTED SEPARATION TECHNOLOGY

With a total of four container sizes and the option of equipping them with stainless steel wear plates, you have the perfect conditions to do your job really well. The 4 m³ container size has been specially developed for two-axle vehicles with an overall width of 2.30 m. This compact size and the tipping axle height of 2.10 m allow the container to be emptied onto smaller transport vehicles. The 6 m³ container is particularly suitable for vehicle chassis with a short wheelbase. The 8 m³ container offers more loading volume and therefore more effective work. It is the optimum size for all 3- and 4-axle chassis. This is most frequently used for suction work in civil engineering. The 10 m³ container is designed for very special suction tasks, for example in industrial plants, which require a large container volume.

OPTIMIZED AIR FLOW

In order to make the suction structure more efficient in all available sizes, the fan performance has been maximized and the air flow inside the container has been modified. The newly designed and patented separation chamber ensures optimum pre-separation of the material. Long air paths to the fine filters dry the air flow. Constant and effective exhaust air purification is achieved with the help of the highly effective fine filters. The fine filter chamber is emptied automatically when tipping. The fine filter cleaning system installed as standard ensures optimum cleaning of the fine filters. This has a positive effect on the service life of the filters and the suction power of the entire machine.

THE STRENGTHS AT A GLANCE:

- High-quality, torsion-resistant steel construction

- Patented air guidance system

- Automatic filter cleaning

- Variable container sizes

- Less noise emission

- Lower filter load

RSP FILTER SYSTEM

The new filter box is designed in one piece and folds out for quick replacement of individual filter cartridges or the entire box in rows. The filter cartridges are mechanically secured and can be easily replaced. To reduce material build-up, the filter box is now without a filter basket. This also makes it easier to clean the filter system.

The optimized separation improves the filter inflow and reduces the filter load. The new filter box is made of stainless steel on the air inlet side.